Revised: 1/6/2013 Subject to Revisions

Crosshead Guides

The crosshead is a fitting on the end of the drive piston shaft that is travels parallel to the piston rod held between guide slide bars. The guide slide bars in turn are mounted between the rear cylinder cover and the front expansion link support frame. The guides must of course be a close fit to the crosshead and parallel to the piston rod and each other.

First Set of Crosshead Guide Slide Bars as Printed

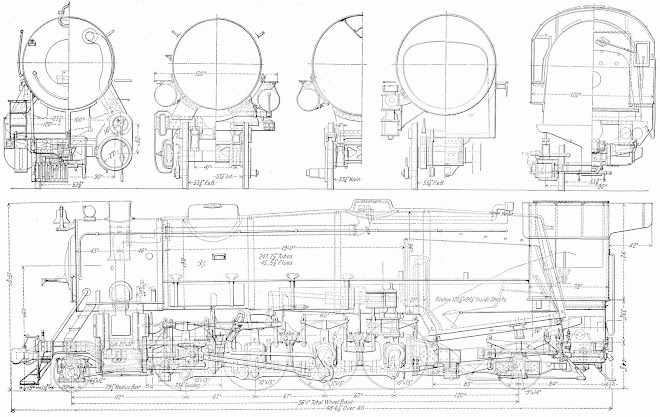

Design details were developed using the Alibre Pro 3D CAD software using drawing information from the USRA Heavy Mikado plans from the Internet. Each had pilot holes in place for the front and rear mounting points. As printed they came out well as shown above. They were done in white ABS to agree with the prototype photograph being used as a guide. The upper part of each guide bar in the above photo is the outside of the part on the locomotive model.

Cross Slide Guide Bars After Removal of Support Material Before Clean up

The guide bars were easily removed but as expected had some support material residue to be removed. Removal was done using the rotary sanding wheel. The top two bars show the typical amount of support strips that remained. The bottom bars show the outside away from supports.

Crosshead Guide Bars After Clean Up

The guide bars cleaned up easily without any problems. After clean up they were drilled at the front end on the left of the photo for 0-80 screws and tapped at right for 00-90 screws. Only one 0-80 screw is used to mount the front but four 00-90 screws were used on each bar in a manner similar to the prototype. This was done because the size of the front expansion lever bracket support provides only a very small mounting region.

Engineer Side Crosshead Slide Bars Installed

Fireman Side Crosshead Slide Bars Installed

Once installed the guide bars were found to be anything but parallel to one another. After examining the issue the author determined that new bars with adjusted position 0-80 screw mounting holes would fix the problem. Also, the guide bars were too wide side to side with insufficient clearance between the inside of the bar and front side rod mounting screw. The author elected to narrow the bars to provide clearance for the crosshead inside to the coupling rod mounting screws on both sides of the locomotive. Because the distances and position were slightly different between the two sides of the locomotive because of tolerance build-ups, the author designed custom bars for both top and bottom and each side of the locomotive.

One Set of Custom Crosshead Slide Bars as Printed

The new design slide bars were marked by designing indent lettering to keep them identified as to which side of the locomotive they were for. The above photo shows the markings highlighted in blue. These also printed very well and in virtually the same fashion as before. They differ only a modest amount.

Modified Engineer Side Guide Bars Installed

Modified Fireman Side Guide Bars Installed

After clean-up the new modified guide bars were installed as before. This time the corrections resulted in parallel bars which also were parallel to the cylinder and the rails below. The narrowed bars also provided enough clearance for the crosshead to front coupling side rod mounting screws.

Crossheads

The crossheads run back and forth between the slides keeping side load pressures from flexing the piston rod. The side loads are caused by the connecting rod attached to the third driver. The crosshead is actually a sandwich that contains the end of the connecting rod on a pin and attaches to the piston rod. In the model the design will consist of one side with the piston rod and the other side with the pin for the connecting rod. The two parts will be held together with 00-90 screws with the inside half being threades and the outside half having clearance holes for the screws.

Set of Crossheads As Printed on 3D Printer

The crosshead set of four parts was printed together as shown in the picture above. One outer section has already been separated from the raft and supports. Each part has flanges to keep the crosshead held on the slides. The inner section has the piston rod. The parts took nearly five hours to print. The results were good. Small dummy bolt heads are located between the connecting screws on the outer sections. There are four screws, two just below the upper slide flange and two more just above the lower slide flange. The outer section has two pins, one insdie for the connecting rod and another outside for the union link that connects to the combination lever. The connecting rod will be held in place by the sandwich halves, the union link with a small screw and washer.

Crossheads After Removal From Raft and Supports

The majority of residual support material (green) was on the interior of the sandwich halves. The picture above shows one set before (upper) and another set after (below) cleanup. Most removal was done with a model knife because of the small size. A file was also used to smooth the flange inside surfaces that would run on the slides.

Crosshead Sets Rigged for Hole Drilling

The crossheads were built with the noles defined in the CAD drawings. Small partial holes and circular printed rings provided the locations for the holes. They required drilling and tapping. First the parts were held tightly together and drilled with the very small #65 drill (0.035" diameter). The halves were then separated and the outer portions drilled through with #55 drill to provide a clearance for the 00-90 screws. The Dremel drill press was used with the tool.

Crossheads Assembled on The Crosshead Slides

Close Up of Assembled Crosshead on Slide

The assembled crossheads fit too tightly on the slides and some further enlargement of the space for the slides was made using a file. The inside and outside halves are bolted together with the four small black 00-90 screws as shown in the photos. The screws used feature a Torx type head which is a star shaped opening to fit a Torx driver. A T2 star driver was used to drive the screws in place. This works suprisingly well for the very tiny screws. Between each pair of holes horizontally are two dummy screw heads (without the star opening). The crossheads are printed in white ABS above and will be painted later.