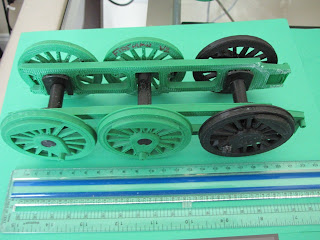

Four sets of development 3D model wheels and axles were used to evaluate glue processing with "super glue" (cynoacryalate - CA). Each wheel-axle set was inserted into the glue tool previously made. One wheel was removed and a small amount of CA was applied around the end of the axle. The wheel was replaced and the fixture bound with rubber bands for a minute or two. Then the opposite wheel was removed and a similar glue process performed. All four sets came out well with no signs of excess glue and strong bonds. Two wheel sets had bearings installed for later evaluation of fit with test frames. The four sets of wheels together give an idea of the size of the model spanning about 10".

Two ABS frames were fabricated using PLA rafts and no supports. The frames were noticeably warped and came out a bit too thick as well. The frames were the middle section of the overall frame which have slots for drivers 2,3 and 4. The holes in the bottom are for the frame keepers that will later be bolted in place after tapping the holes for small machine screws.

The frames are near 8" long and greatly exceed the maximum recommended size for ABS parts of 100mm (3.93"). The warps are therefore as predicted by BFB. Some of the small details are visible on the right hand side of one of the frames. The warps prevented the other frame from exhibiting the same rivet detail.

The first trial fit of the wheels with bearings into the two end slots went well. The bearings slide up and down freely. The wheels roll freely. The warped frames are not usable in their present condition. A pair of the same middle frames will be fabricated in PLA to determine whether those will work better. The PLA parts will use ABS raft and supports. In past those sometimes come loose from the build platform and should that happen the frames will be distorted.

Hi buddy, your blog’s design is simple and clean and i like it. Your blog posts are superb. Please keep them coming. gagan enterprises

ReplyDelete