The front main chassis was divided into four approximately 4" long sections. A pair of one of the sections was printed using PLA raft and ABS parts, no supports were required. As can be seen above, even the relatively short sections of ABS warped significantly when printed horizontally. The chassis frame must be straight due to it's close fit with many other parts. The amount of warp above will not work.

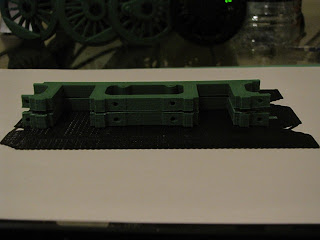

Another attempt was made with one of the frame sections standing vertical in the printer. This meant many support columns to deal with the many overhangs present with the part in this orientation. The picture above shows the part still embedded in ABS support material. In this print example, the raft, support and part are all ABS. More than likely removal from the supports will be problematic as all are the same color. An order of black ABS just arrived so in future the model parts will be black ABS or PLA and raft and supports will be of a contrasting color. The as printed part looks like a model of a skyscraper, most of the vertical walls are the outer portions of supports. The BFB-3000 printer can readily lay thin section vertical walls in place with good alignment layer by layer. Hopefully the part can be separated non-destructively. At first glance the part looks square and does not appear warped in any degree. This may be due to the fact that it is free standing with no material with a different coefficient of expansion in tight contact.

Perhaps it would work reasonably well to use ABS supports and a PLA model, or vice. Alternates will likely be tested to determine the overall best approach for the complex vertical models of the frame.

No comments:

Post a Comment