The middle chassis side frames are a bit over 8" long. The first effort to build a pair was made using ABS for the parts with PLA raft and no supports. The frames have three wheel bearing slots. From left to right they are for the intermediate driver, main driver and back driver. The front driver slot is part of the front frame structure. The prototype locomotive frames are essentially one piece encompassing the front and middle sections of the model, however, those would have been too large for the 3D printer size capacity of 9" or 10" depending on orientation. Consequently the chassis was divided into two parts so they halves would fit within the limits of the printer. This section was chosen to permit fit checks with the wheels and bearing proof parts previously built.

As can be seen in the above photo, the frames warped substantially. The view shows the bottoms of the frames where the small holes for machine screws were included. Those holes are primarily to locate the positions for drill and tap to accept small 0-80 machine screws that hold the frame keepers in place. The frame keepers are bars that hold the bearing blocks in place. On the prototype the keepers provide considerable stiffening of the frame in the long dimension as well. In the background are the four wheel and axle sets glued during a prior effort.

After building the ABS frame sides, the printer build file was configured to build PLA frames on ABS raft with ABS supports. As the first couple of layers of PLA were applied it became apparent that the ABS was coming loose and strands were separating from the base layer. The printing was stopped at the point shown in the above photo. The loose strands of green ABS are clearly visible. Those in turn caused the PLA layers to be highly distorted and dislocated.

Shown above is a photo of the overall print pattern for the two side frame members on the printer build bed. The loose ABS raft strands are clearly visible. This photo was taken just prior to removal from the machine.

The above and below photos show a close up view of the loose strands and heavily distorted black PLA print layers above the strands. It is clear that the resulting PLA print would have very poor and essentially useless.

After examining the results of the PLA attempt, a decision to retry using the finest Z layer dimension was made. The above print attempt was made using 0.25mm Z layers. The next photo shows that result in the upper part of the photo and a reprint using 0.125mm Z layers in the next attempt in the lower part of the photo.

The finer Z layers resulted in a more secure ABS raft structure, however, the raft lifted slightly from the build platform at the right side during the printing process resulting in warped frame pieces. Also, the right hand portion of the bottoms (bottoms shown in the photo) were badly printed and would require considerable effort to repair, probably impractical. Consequently, the admonition to avoid using ABS for runs longer than 100mm is clearly born out in both cases.

The main conclusion to be drawn are that it will not be feasible to build the frames in sections so large as 8". The frame will now be broken up into portions of about 4" which will then be glued together to form the overall main frame some 15+" long. Another conclusion reached is that the frames can be either ABS or PLA depending on how well the smaller parts print out. One issue is to determine a good interface between sections that will help align them and provide a strong joint without the need to use external reinforcement that would be non-prototypical.

Tuesday, December 13, 2011

Sunday, December 11, 2011

Gluing Wheels and Axles - First Frame Print

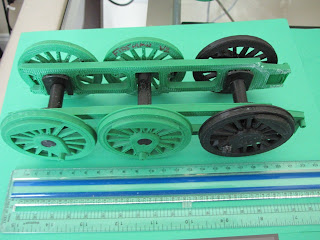

Four sets of development 3D model wheels and axles were used to evaluate glue processing with "super glue" (cynoacryalate - CA). Each wheel-axle set was inserted into the glue tool previously made. One wheel was removed and a small amount of CA was applied around the end of the axle. The wheel was replaced and the fixture bound with rubber bands for a minute or two. Then the opposite wheel was removed and a similar glue process performed. All four sets came out well with no signs of excess glue and strong bonds. Two wheel sets had bearings installed for later evaluation of fit with test frames. The four sets of wheels together give an idea of the size of the model spanning about 10".

Two ABS frames were fabricated using PLA rafts and no supports. The frames were noticeably warped and came out a bit too thick as well. The frames were the middle section of the overall frame which have slots for drivers 2,3 and 4. The holes in the bottom are for the frame keepers that will later be bolted in place after tapping the holes for small machine screws.

The frames are near 8" long and greatly exceed the maximum recommended size for ABS parts of 100mm (3.93"). The warps are therefore as predicted by BFB. Some of the small details are visible on the right hand side of one of the frames. The warps prevented the other frame from exhibiting the same rivet detail.

The first trial fit of the wheels with bearings into the two end slots went well. The bearings slide up and down freely. The wheels roll freely. The warped frames are not usable in their present condition. A pair of the same middle frames will be fabricated in PLA to determine whether those will work better. The PLA parts will use ABS raft and supports. In past those sometimes come loose from the build platform and should that happen the frames will be distorted.

Friday, December 9, 2011

Busy Making Locomotive Drivers and Axles

During this past couple of months many attempts to make good drivers and axles were made. The picture shows a collection of black PLA, Green ABS and one white ABS wheel, seventeen drivers in all. Also shown are five axles on the table plus two more inside the assembled driver sets at the top. Each driver takes about 3hr 30m to build and axles take a bit longer, so the BFB-3000 3D printer has been steadily in use.

The main difficulties have been getting good definition of the wheel flange and good finish and detail on the wheel surface. Attempts included using various combinations of raft and wheel material. The best overall results are obtained using PLA raft and supports with ABS wheel material. Conversely, for the axles, the best results are obtained using ABS raft and supports with PLA axle material. All parts required post build clean-up to remove raft and support material and small strings of build material.

The next step will be to glue together examples to determine the best method of permanent assembly. BFB indicated that super glue is a good candidate for bonding. At the top of the photo on the left side is a gluing fixture fabricated to space the wheels accurately and hold them squarely aligned during the gluing process. That assembly with rubber bands consists of two half shells of a round spacing tool held with blue rubber bands, two wheels and an axle held with tan rubber bands. Not visible are two bearings that are inside the clam-shell spacer on the axle. At the right on top is an assembled wheel-axle pair with bearings on the axle shaft. The bearings of course are free to rotate on the axle. The bearings will interface with slots on the locomotive frame to provide a way for the wheels to slide up and down for operation of the equalization system and freely rotate as the locomotive moves on the rails.

Glue procedures will be worked out using some of the wheels and axles shown above, but none of these will be used in the final model locomotive. Black ABS material has been ordered from BFB to manufacture the final model wheels. Black PLA is already on hand for the axles and bearings.

Wednesday, December 7, 2011

Driver - Axle Assembly Tool

Since the drivers are a bit loose on the axle, an assembly tool was built that provides near exact spacing and squareness. The tool is a two part clam shell arrangement that is hollow inside to provide room to hold two bearing assemblies. The bearings rotate freely on the axle. Two are shown on the axle in one half of the tool at left.

Another two bearings are shown at the left side of the picture still inside the raft and support assembly. The bearings are PLA while the raft and support are green ABS. This worked out well before using translucent PLA and was continued here. The bearing assembly was adjusted to better fit on the axle and provide more room to slide up and down in the frame slot.

The tool came out a bit too wide giving an incorrect value for the wheel gauge. The 3D CAD drawing was revised and new tool parts will be printed to slightly smaller dimensions to adjust the gauge to more correct value.

Another two bearings are shown at the left side of the picture still inside the raft and support assembly. The bearings are PLA while the raft and support are green ABS. This worked out well before using translucent PLA and was continued here. The bearing assembly was adjusted to better fit on the axle and provide more room to slide up and down in the frame slot.

The tool came out a bit too wide giving an incorrect value for the wheel gauge. The 3D CAD drawing was revised and new tool parts will be printed to slightly smaller dimensions to adjust the gauge to more correct value.

Tuesday, December 6, 2011

More tests of ABS for locomotive wheels

Quite a few trials to build driver wheels were made using both black PLA and green ABS materials. Also the raft and support thickness was varied in attempts to obtain good definition of the flange and other wheel features. Shown in the picture are two complete wheel axle sets and three additional wheels.

The complete wheel axle sets are all PLA except for one ABS wheel. On the table top are another PLA wheel and two more ABS wheels. It takes about 5hr 30min to build one wheel, so the printer has been busy.

Since flange definition is variable with PLA, ABS seems to achieve better results. The wheel in center was built with printer Z axis layer size of 0.125mm. Looking closely you can barely make out the extrusion threads. Some small gaps are evident. This wheel was made on a 0.05" raft. It has good flange definition. However, separation of the PLA raft delaminated about half the flange layer. This was due to the extreme stiffness of the PLA raft and support layer.

The wheel at left was built using 0.25mm printer Z layers. The extrusion tracks are clearly evident. This wheel has good flange definition, however, it would require much work to fill the surfaces and make it look solid. This was printed using standard raft thickness which resulted in a flexible raft and support layer. This enabled relatively easy removal by bending with fingers.

After several trials, it was concluded that for ABS the printer Z axis layer thickness should be 0.125mm with a standard PLA raft thickness. This permits relatively easy removal of the raft due to it's flexibility and leaves little raft or support material to be removed. Also, surface definition is quite good. Should this be fabricated in black ABS or painted, or both, most of the small gaps would essentially disappear. PLA wheels have as good a definition, however, they generally suffer poor flange definition due to material warps.

Interestingly the axle holes of all wheels are essentially identical and fit the revised axles well. The PLA axles came out well and require little work to prepare them for assembly.

The complete wheel axle sets are all PLA except for one ABS wheel. On the table top are another PLA wheel and two more ABS wheels. It takes about 5hr 30min to build one wheel, so the printer has been busy.

Since flange definition is variable with PLA, ABS seems to achieve better results. The wheel in center was built with printer Z axis layer size of 0.125mm. Looking closely you can barely make out the extrusion threads. Some small gaps are evident. This wheel was made on a 0.05" raft. It has good flange definition. However, separation of the PLA raft delaminated about half the flange layer. This was due to the extreme stiffness of the PLA raft and support layer.

The wheel at left was built using 0.25mm printer Z layers. The extrusion tracks are clearly evident. This wheel has good flange definition, however, it would require much work to fill the surfaces and make it look solid. This was printed using standard raft thickness which resulted in a flexible raft and support layer. This enabled relatively easy removal by bending with fingers.

After several trials, it was concluded that for ABS the printer Z axis layer thickness should be 0.125mm with a standard PLA raft thickness. This permits relatively easy removal of the raft due to it's flexibility and leaves little raft or support material to be removed. Also, surface definition is quite good. Should this be fabricated in black ABS or painted, or both, most of the small gaps would essentially disappear. PLA wheels have as good a definition, however, they generally suffer poor flange definition due to material warps.

Interestingly the axle holes of all wheels are essentially identical and fit the revised axles well. The PLA axles came out well and require little work to prepare them for assembly.

Sunday, December 4, 2011

Modifying Part Designs To Obtain Proper Fit

By modifying the 3D design model the axle and drivers fit together much better. A modest amount of filing and grinding were done to optimize the fit. The wheels slide snugly unto the axle. The picture at left shows one pair and axle completed and the second pair awaiting printout of one driver as this blog entry was written.

The wheel gauge is off a bit, somewhat too wide for the design goal of 1/2" to the foot of american standard gauge of 4' 8 1/2". The axle length will be adjusted to bring the gauge closer to scale dimension.

The approach being taken is to now build sample PLA parts on ABS raft and support structure, check fit and key dimensions, adjust the design to correct any significant errors and build new parts. This seems to be working. It will take longer and use more material, however, the machine repeats build sizes fairly well and it appears that this method can achieve the desired scaling.

The drivers built for the above picture are used for the front and back pair of the Mikado locomotive. Two other sets are needed, the intermediate pair and the main pair. Before assembly of the driver and axle sets, the bearings need to be fabricated and slipped on the axles.

The wheel gauge is off a bit, somewhat too wide for the design goal of 1/2" to the foot of american standard gauge of 4' 8 1/2". The axle length will be adjusted to bring the gauge closer to scale dimension.

The approach being taken is to now build sample PLA parts on ABS raft and support structure, check fit and key dimensions, adjust the design to correct any significant errors and build new parts. This seems to be working. It will take longer and use more material, however, the machine repeats build sizes fairly well and it appears that this method can achieve the desired scaling.

The drivers built for the above picture are used for the front and back pair of the Mikado locomotive. Two other sets are needed, the intermediate pair and the main pair. Before assembly of the driver and axle sets, the bearings need to be fabricated and slipped on the axles.

Friday, December 2, 2011

Another Attempt at PLA part on PLA raft

A second attempt to fabricate PLA parts on a PLA raft with PLA supports was made. The Wheel-Axle Kit was used with revised axle diameter and axle hole diameter. The ensemble is shown at left after build. The raft was made thicker in order to obtain a better release as was experienced with the axle part on the previous build.

After the build an attempt was made to remove the raft and supports using finger and later pliers pressure. As for the previous build, the axle was removed relatively easy while the raft under the wheels was again attached very strongly making removal essentially impossible. A short effort was made using a Dremel tool and cutter tool to remove the white PLA material. It of course is ground away, but only slowly and with very little control. It would likely require a tool more precise such as a milling machine to remove the raft material. This build method is impractical for large flat parts like the wheels.

After the build an attempt was made to remove the raft and supports using finger and later pliers pressure. As for the previous build, the axle was removed relatively easy while the raft under the wheels was again attached very strongly making removal essentially impossible. A short effort was made using a Dremel tool and cutter tool to remove the white PLA material. It of course is ground away, but only slowly and with very little control. It would likely require a tool more precise such as a milling machine to remove the raft material. This build method is impractical for large flat parts like the wheels.

Subscribe to:

Posts (Atom)