3/8/2013 Subject To Revisions

Overall Boiler Design

The boiler including the firebox of the prototype locomotive is about 36' long, roughly the wheelbase. The model is 1/24th scale so the boiler would be about 1.5' long. That is much too large for the printer. The largest dimension is about 10". Consequently the author elected to build the boiler in sections. Arbitrarily these are the smokebox, sanddome, transition, steamdome, and firebox. The firebox might be done in two halves or one piece depending on how well the other sections come out on the 3D printer.

Smokebox

The design of the smokebox includes three parts, the boiler smokebox section, the smokestack and the smokebox front. The author contemplates glueing the smokestack in a mating hole in the boiler smokebox section and attaching the front using five 00-90 screws.

3D CAD Model of the Boiler Smokebox Assembly

The above illustration shows the smokebox assembly. The front is held in place with the five small black 00-90 screws while the smokestack will be glued in place. The smokebox assembly will be used to attach the front of the boiler to the cylinder assembly on the locomotive model with access to the hold down screw through the smokestack opening. This section is 3.86" along it's axis, 3.75" in diameter and about 4.4" tall including the smokestack.

Boiler Smokebox Section Design

The boiler smokebox section illustrated above is essentially a tube 3.53" long and 3.75" in diameter. The tube wall is 0.111" thick. A hole on the top will accommodate the smokestack part. In the inside bottom is a boss for the 4-40 front boiler hold down screw that threads into the cylinder assembly on the locomotive chassis. Five small screw holes around the front will be threaded for 00-90 screws that will attach the front to the cylinder. The back will eventually be glued to the boiler sandbox section. Dummy rivets are placed around the front and rear where the cylinder is riveted to the internal rings on the prototype. The front ring is used to provide attachment of the smokebox front and the rear ring attaches to the next boiler cylinder, the sandbox section.

Because of the parts size, it will be printed with the cylinder standing with the front up. The boss for the attachment screw is tapered at 45 degree angles to allow the fabrication without support materials. The smokestack opening will require support from the base, the back of the cylinder in this case. No other supports are required to fabricate this part in this manner. This part has already been through the Axon software to create the build code for the 3D printer. The smokebox cylinder will take over 16 hours to print and requires some 369 layers of printing to complete the 3.75" height of the cylinder sitting upright.

Smokestack

The smokestack is slightly tapered and has a flanged ring that curves to match the radius of the smokebox boiler cylinder. The author shortened the bottom portion below the flange as interior details of the smokebox are not being modeled. The bottom portion passes through the hole in the cylinder. The curved flange portion will be glued to the top of the cylinder.

Smokebox Front

The smokebox front is a complicated design with many details. The outer ring of bolts are fake details to model the bolt ring on the prototype, Five of those are replaced with 00-90 screws to hold the front to the cylinder. The inner door is a non-working model with the clamps and door hinges as details. The small flat section at the bottom of the inner door is for the headlight bracket.

The three parts are shown mated together in the first illustration above. On the 3D CAD model the assembly is done to check alignment and fit of the various parts. Based on that this section should go together needing only cleanup after printing along with drilling and tapping the holes for the screws. The hold down screw hole on the inside bottom is not tapped but provides slide fit clearance for the 4-40 screw. The small holes in the front cover are slide clearance fit for the 00-90 screws while the holes in the main cylinder for those screws will be drilled and tapped for the 00-90 screws.

Smokebox Section Build

The build on the 3D printer was done in three sub-sections, boiler tube section, smoke stack and smokebox front. Each was built using the 3D CAD designs shown previously.Boiler Tube Section

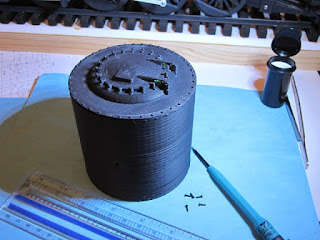

Completed Smokebox Boiler Tube Section in 3D Printer

Smokebox Boiler Section as Printed

Because the smokebox boiler section is built in 360+ layers each having a fair amount of material, it takes a long time to print; 16h 50min. As can be seen in the above photos the layers are distinctly visible. Each layer is very close to the same size, but since the material is actually a round thread the boundaries show when looking at the printed item. A mounting boss was built in as shown inside the section. A round hole defines the location of the smoke stack. If you look close at the full size photo a single ring of rivet details are located at the front and a double row at the back of the tube.

Smokebox Boiler Tube Section During Fit Check With Cylinder Saddle

Good Fit of the Two Mating Curved Surfaces

The smokebox boiler tube section was temporarily mounted on the cylinder saddle for a fit check which came out very well.

Smoke Stack As Printed in 3D Printer

Bottom of Smoke Stack After Removing Bulk of Support Material

The next part printed was the smoke stack. This part required 3h 58min to complete. The part had good shape definition. Some support material was on the top of the flange fairing between the stack and boiler. Residual support material on both top and bottom were removed using the Dremel tool with a small round cutter. Most of the top residual was removed using a model knife.

Smoke Stack Fit on Smokebox Boiler Section During Fit Check

Smokebox With Stack in Position on Locomotive Cylinder

Photo of Smokebox With Ruler

The smoke stack fit well on the boiler after removing residual support material. The double curved fillet between the stack and boiler was difficult to design, but the finished part fits very well. The smoke stack will later be glued in place.

Smokebox Boiler Section With Attachment Screw Installed

The cylinder assembly was tapped for a 4-40 hold down screw. The small hole in the boiler bottom was drilled out to provide slide clearance for the screw. The above photo shows the screw in place.

Smokebox Front in 3D Printer After Completion

Completed Smokebox Front With Support Material

The smokebox front was next in the 3D printer taking 8hr 31min to print. A considerable amount of support material is underneath the domed front of the part. The level of detail was fairly good with the small bolts coming out as circles. Once again the layering of the printer is clearly visible particularly on close inspection. The fine detail of the various shapes looks like a terraced hillside with most of the sharp corners rounded. From a bit of a distance the part looks quite good.

Smokebox Front on Smokebox During Fit Check

Closer View of Smokebox Front

The bulk of the support material was removed leaving a thin layer around the interface flange at the edge of the smokebox front. The part has an alignment ring on the back which fits closely inside the boiler. The part slides in place slightly snug and would hold in place without screws. However, the outer ring would show the residual support material between the smokebox front and boiler. The author decided that the best way to remove it was to use the Sherline CNC mill.

Back of Smokebox Front After Removal of Residual Support Material on Outer Flange

Closeup of Smokebox Front After Removal of Residual Support Material

The smokebox front was carefully aligned on the mill rotary table so that the cutter would follow the outer flange. All the residual material was then milled away. For this operation all movements of the mill were manually controlled as the rotary table would follow the shape easily. Residual material on the middle portions of the part were left in place.

Smokebox Front and Boiler Being Drilled With Tap Holes

Smokebox Front Being Drilled With Clearance Holes

Boiler Section After Being Tapped for 00-90 Screws

The next step is to drill and tap the five holes used to hold the smokebox front in place. This was done on the Dremel drill press using a very small #65 drill (0.035" diameter). The boiler section was sized to provide adequate material for the screw threads. After drilling the front and boiler together to assure hole position alignment, the front was removed and drilled with clearance #55 drill holes (0.042" diameter).

Boiler Smokebox Front on Smokebox During Assembly

Smokebox Front with 00-90 Screws in Place

Closeup of Screw Partially Installed

Assembly was painless as the holes were all aligned. The second photo shows the front with the attachment screws in place. The closely match the dummy bolt ring around the rim. The bottom photo shows a closeup of one screw and the surrounding details. The closeup clearly shows the level of detail and the layering effect of the printing process.

Smokebox Assembled and Installed on Locomotive Model

With the exception of gluing the smoke stack in place the smokebox section of the boiler is completed less the many smaller details that will be added later. The author found the need for a longer crosspoint screwdriver to reach the attachment bolt at the bottom inside.

The boiler sections are projected to be glued together making one long assembly including the firebox and cab. Another bolt or bolts at the rear portion will hold that end of the boiler to the locomotive chassis while the bolt accessed through the smoke stack hold down the front.